What is a solar panel?

Solar panel electricity systems, also known as solar photovoltaics (PV), capture the sunâs energy (photons) and convert it into electricity. PV cells are made from layers of semiconducting material, and produce an electric field across the layers when exposed to sunlight. When light reaches the cell, some of it is absorbed into the semiconducting material and causes electrons to break loose and flow. This flow of electrons is an electric current, that can be drawn out and used for powering outside devices. This current, along with the cellâs voltage (a result of built-in electric fields), define the power that the solar cell is capable of producing. It is worth mentioning that a PV cell can produce electricity without direct sunlight, but more sunshine equals more electricity.

A module, or panel, is a group of cells connected electrically and packaged together. several panels can also form an array, which can provide more electricity and be used for powering larger instruments and devices.

Different kinds of Solar cells

Solar cells are roughly divided into three categories: Monocrystalline, Polycrystalline and Thin Film. Most of the worldâs PVs are based on a variation of silicon. The purity of the silicon, or the more perfectly aligned silicon molecules are, affects how good it will be at converting solar energy. Monocrystalline solar cells (Mono-Si, or single-crystal-Si) go through a process of cutting cylindrical ingots to make silicon wafers, which gives the panels their characteristic look. They have external even coloring that suggests high-purity silicon, thus having the highest efficiency rates (typically 15-20%). They are also space efficient (their efficiency allows them to be small) and live longer than other kinds of solar panels. Alas, they are more expensive than other kinds and tend to be damaged by external dirt or snow.

Polycrystalline silicon (p-Si or mc-Si) solar cells do not go through the abovementioned process, and so are simpler and cost less than Monocrystalline ones. Their typical efficiency is 13-16%, due to lower silicon purity. They are also bigger and take up more space.

Thin-Film solar cells (TFSC), are made by depositing one or several thin layers of photovoltaic material onto a substrate. Different types of TFSCs are categorized by which photovoltaic material is deposited onto the substrate: Amorphous silicon (a-Si), cadmium telluride (CdTe), copper indium gallium selenide (CIS/CIGS), polymer solar panels and organic photovoltaic cells (OPC). Thin-film modules have reached efficiencies of 7-13%. Their mass production is simple, they can be made flexible and are potentially cheaper to manufacture than crystalline-based solar cells. They do, however, take up a lot of space (hampering their use in residential applications) and tend to degrade faster than crystalline solar panels.

Solar power advantages and disadvantages

Solar power is free and infinite, and solar energy use indeed has major advantages. It is an eco-friendly, sustainable way of energy production. Solar energy systems today are also much cheaper than they were 20 years ago, and save money in electricity expenses. In addition, it is a much environmentally cleaner form of energy production that helps reduce global warming and coal pollution. It does not waste water like coal and nuclear power plants and is also considered to be a form of energy that is much safer for use.

Although solar power production is widely considered to be a positive thing, some downsides require mentioning. The initial cost of purchasing and installing solar panels can be substantial, despite widespread government subsidy programs and tax initiatives. Sun exposure is critical and so location plays a significant role in the generation of electricity. Areas that are cloudy or foggy for long periods of time will produce much less electricity. Other commonly argues disadvantages regard insufficiency of produced electricity and reliability issues.

Solar power applications

Common solar energy applications include various residential uses such as solar lighting, heating and ventilation systems. Many small appliances utilize solar energy for operation, like calculators, scales, toys and more. Agriculture and horticulture also employ solar energy for the operation of different aids like water pumps and crop drying machines. The field of transportation has been interested in solar powered vehicles for many years, including cars, planes and boats that are vigorously researched and developed. Solar energy also has various industrial applications, ranging from powering remote locations as well as space and satellite systems, to powering transportation signals, lighthouses, offshore navigation systems and many more.

Solar technologies are vigorously researched, aiming to lower costs and improve existing products as well as integrate PV systems in innovative products like PV-powered curtains, clothes and laptop cases.

Graphene and solar panels

Graphene is made of a single layer of carbon atoms that are bonded together in a repeating pattern of hexagons. It is a 2 dimensional material with amazing characteristics, which grant it the title âwonder materialâ. It is extremely strong and almost entirely transparent and also astonishingly conductive and flexible. Graphene is made of carbon, which is abundant, and can be a relatively inexpensive material. Graphene has a seemingly endless potential for improving existing products as well as inspiring new ones.

Solar cells require materials that are conductive and allow light to get through, thus benefiting from graphene's superb conductivity and transparency. Graphene is indeed a great conductor, but it is not very good at collecting the electrical current produced inside the solar cell. Hence, researchers are looking for appropriate ways to modify graphene for this purpose. Graphene Oxide (GO), for example, is less conductive but more transparent and a better charge collector which can be useful for solar panels.

The conductive Indium Tin Oxide (ITO) is used with a non-conductive glass layer as the transparent electrodes in most organic solar panels to achieve these goals, but ITO is rare, brittle and makes solar panels expensive. Many researches focus on graphene as a replacement for ITO in transparent electrodes of OPVs. Others search for ways of utilizing graphene in improving overall performance of photovoltaic devices, mainly OPVs, as well as in electrodes, active layers, interfacial layers and electron acceptors.

Commercialization efforts

While graphene-based solar cells are not currently commercially available, some efforts are bearing fruit in regards to the use of graphene in auxiliary aspects of PV. One such example is ZNShine Solar's G12 evolution era series - comprised of a 12-busbar graphene module, 5-busbar graphene module and double-glass graphene module. According to reports, the application of ZS's graphene film layer increases light transmission performance of the glass itself. In addition, Znshine Solar's modules are self-cleaning. In July 2018, ZNShine Solar won the bid to provide 37.5MW of PV modules to Bharat Heavy Electricals Limited (BHEL), India's largest power generation equipment manufacturer. According to the contract, 10% of the shipment will be graphene-coated solar panels. In June 2019, Znshine Solar announced signing a 100MW graphene-enhanced solar module supply agreement with UAE's Etihad Energy services.

Further reading

The latest graphene solar news:

HydroGraph to supply graphene to Volfpack Energy for solar power battery storage

HydroGraph Clean Power has announced that its flagship graphene product, FGA-1, has been chosen by Volfpack Energy, a hardware company focused on using supercapacitor technology to increase the adoption of renewable energy across Asia.

Its flagship product, fractal graphene, FGA-1, was chosen by Volfpack to be the base material of the supercapacitor design after Volfpack’s engineers determined that it outperformed materials traditionally used in supercapacitors, such as activated carbon, by 4x.

Researchers review graphene's potential and limitations for cooling solar panels

Researchers at Monash University Malaysia and Tunku Abdul Rahman University of Management and Technology have studied how graphene and graphene derivatives could be used as materials to reduce the operating temperature of solar panels. They reviewed the limitations and potential of solar module cooling techniques based on graphene and found that high costs and graphene treatments are the main challenges to overcome.

In a recent in-depth review, the team explained that graphene has attracted the interest of the scientific community as a medium to enhance heat transfers in cooling systems. When used for PV cooling applications, graphene can be used in different ways. For example, as a selective absorber coating or embedding it into a working fluid as a nanofluid. Graphene nanoparticles can also be added to thermal interface materials (TIMs) or phase change materials (PCMs) used for solar module cooling.

First Graphene, Halocell and QUT secure funding for graphene-enhanced perovskite PV project

First Graphene has announced an R&D collaboration with Greatcell Energy, trading as Halocell Energy, and the Queensland University of Technology (QUT) to commercialize perovskite solar cell fabrication. The project has received a Cooperative Research Centers Project (CRC-P) grant worth over AUD$2 million (around $USD1,300,000).

The research and development project is intended to commercialize ultra-low-cost, flexible perovskite solar cell fabrication using Halocell’s roll-to-roll production process at the company’s Wagga Wagga plant, First Graphene said in an announcement. Through the project, First Graphene plans to develop cost-effective graphene-based electrode replacements for high-cost conductor materials, such as gold and silver, used in cell manufacturing.

First Graphene collaborates with Greatcell Australia on graphene-enhanced perovskite solar cells

It was recently reported that First Graphene is working with solar company Greatcell Australia on graphene enhancements to perovskite solar cell technology.

Perovskites are a family of materials with a unique crystal structure that have potential for many applications, the most prominent of which is low cost, efficient solar cells. Greatcell Australia has established a pilot plant in New South Wales and is in the advanced stages of testing its range of perovskite solar cells (PSCs) with manufacturers around the world. Greatcell is aiming to fit its modular production lines into 40-foot shipping containers, due in part to the easier assembly and reduced number of steps to produce PSCs compared to silicon solar cells.

The Graphene Flagship's chief, Prof. Jari Kinaret, shares his views on the latest graphene development and the post-Flagship future

The Enlit Europe 2022 energy conference recently took place, and the Graphene Flagship participated, showing some of the latest energy-related graphene projects. We took the chance to discuss graphene with some of the flagship researchers, and we also talked to Prof. Jari Kinaret, the director of the flagship project, to learn of how he summarizes the last 10 years now that the flagship project will soon end.

Q: We understand that the Graphene Flagship is attending Enlit Europe 2022, showing some new graphene R&D projects. We'll be happy to get an overview of what will be displayed at the event.

At Enlit Europe, the Graphene Flagship exhibited innovations from its Spearhead Projects, which are industry-led initiatives working to move materials from research labs towards commercial applications. Among these initiatives are:

- CircuitBreakers, led by ABB and developing first-of-their-kind grease-free, maintenance-free, low-voltage circuit breakers for fault protection in key parts of the electrical grid;

- GRAPES, led by Enel Green Power and working on combining silicon solar cells with perovskite solar cells, paving the way for low-cost, highly efficient photovoltaic energy, surpassing the limits of silicon based cells.

Nanotech Energy Europe enters agreement to supply graphene-based battery energy storage systems (BESS) in Greece

Nanotech Energy Europe, a fully owned subsidiary of Nanotech Energy, has announced it has signed a purchase agreement to supply 1+ GWh size BESS (battery energy storage systems), based on graphene technology, through 2028 to Smile Energy in Athens, Greece.

Nanotech stated that the partnership with Smile Energy will allow the immediate expansion of Nanotech's energy storage business to a region which has committed to developing the world's preeminent solar infrastructure. Together, Nanotech and Smile will play a role in supporting Greece and the surrounding region to take the next steps to ensure stability of infrastructure and continuity of energy supply.

Researchers integrate large-area graphene-perovskite solar panels into stand-alone solar farm

An international research group, including teams from CHOSE at the University of Rome Tor Vergata, Hellenic Mediterranean University in Greece and others, has developed a large-area perovskite solar panel with graphene-doped electron transporting layers (ETLs) and functionalized molybdenum disulfide (fMoS2) buffer layers inserted between the perovskite layer and the hole transporting layer (HTL).

The team reported that with increasing temperatures, the module exhibited a smaller drop in open-circuit voltage than commercially available crystalline silicon panels.

Zero Emissions Developments seeks funding to establish graphene-based solar battery manufacturing plant

Zero Emissions Developments (ZED) is an Australia-based company that has announced the development of a technology to build longer lasting, greener, more efficient and more affordable graphene-based solar and EV batteries. It is now seeking AUD$30 million (around USD$22,300,000) in private investment to build a manufacturing plant that will produce these batteries.

The planned manufacturing plant will produce the PowerCap batteries in southeast Queensland through the entity, PowerCap Un Ltd.

Researchers demonstrate how graphene can improve perovskite solar cells

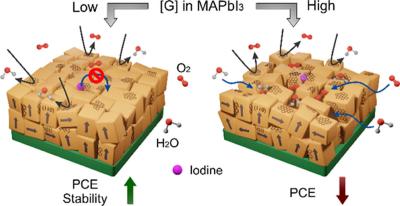

Recent research has shown that the incorporation of graphene-related materials improves the performance and stability of perovskite solar cells. Graphene is hydrophobic, which can enhance several properties of perovskite solar cells. Firstly, it can enhance stability and the passivation of electron traps at the perovskite’s crystalline domain interfaces. Graphene can also provide better energy level alignment, leading to more efficient devices.

In a recent study, Spain-based scientists used pristine graphene to improve the properties of MAPbI3, a popular perovskite material. Pristine graphene was combined with the metal halide perovskite to form the active layer of the solar cells. By analyzing the resulting graphene/perovskite material, it was observed that an average efficiency value of 15% under high-stress conditions was achieved when the optimal amount of graphene was used.

Cambridge team designs GO-enhanced light rechargeable Lithium-Ion batteries

University of Cambridge researchers have designed a lithium-ion battery that can be directly charged in sunlight. This was done in an effort to improve the general process of connecting solar panels to batteries to store energy when the sun is shining.

The idea is to simplify how solar energy is harvested and stored, says Michael De Volder, a mechanical engineer at the University of Cambridge who led the work. If the team can improve the efficiency and lifetime of the hybrid device, its cost will likely be lower than combining solar cells and batteries. For the price of a battery, you get both functionalities, he says.

Pagination

- Page 1

- Next page